Stainless Steel Square Tube: Unlocking the Potential of a Versatile Material

Introduction

Welcome to an in-depth exploration of stainless steel square tubes, a versatile and indispensable component across various industries. This article aims to unravel the multifaceted nature of these tubes, shedding light on their composition, applications, global impact, and future prospects. By delving into these aspects, we will uncover why stainless steel square tubes are not just metal components but powerful enablers of innovation and progress.

Understanding Stainless Steel Square Tube: Unveiling the Basics

Definition:

A stainless steel square tube is a type of structural element crafted from stainless steel, characterized by its rectangular cross-section with equal dimensions in all directions. It is essentially a solid, hollow metal component that maintains its shape under various stresses and environmental conditions.

Core Components:

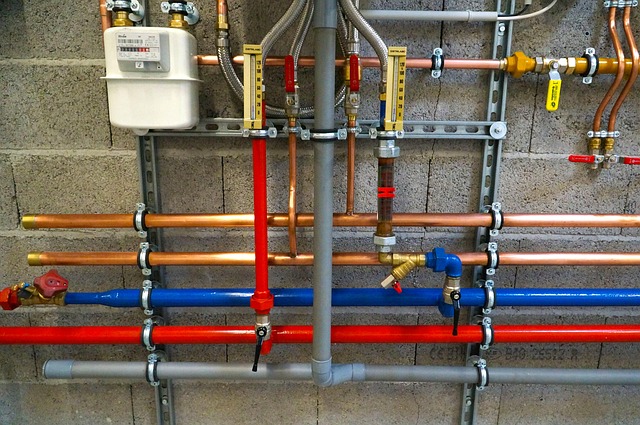

- Stainless Steel: The primary material is stainless steel, an alloy renowned for its exceptional corrosion resistance, durability, and aesthetic appeal. Common grades include 304 and 316, offering optimal performance in diverse environments.

- Shape: The defining feature is its square shape, providing stability and structural integrity. This design makes it suitable for applications demanding strength and rigidity.

- Dimensions: These tubes come in various sizes, typically measured by their outer diameter (OD) and wall thickness. Standard dimensions range from 1 inch to several inches, catering to diverse construction needs.

Historical Context:

The concept of stainless steel square tubes traces back to the early 20th century when the need for corrosion-resistant materials grew, particularly in marine and architectural applications. In the 1930s, the development of austenitic stainless steel, like grade 304, revolutionized industries, leading to increased adoption of stainless steel tubing. Over time, improvements in manufacturing techniques and material science have enhanced their versatility and availability worldwide.

Significance:

Stainless steel square tubes play a pivotal role in numerous sectors due to their unique combination of properties:

- Corrosion Resistance: The primary advantage lies in their ability to withstand corrosive environments, making them ideal for outdoor applications and harsh conditions.

- Strength and Durability: These tubes offer superior structural integrity, ensuring they can support significant loads without compromising strength.

- Versatility: They find use in diverse fields, from construction and architecture to automotive and medical equipment manufacturing.

Global Impact and Trends: A World-Wide Phenomenon

International Influence:

Stainless steel square tubes have transcended geographical boundaries, becoming a global phenomenon. Their demand is driven by various factors across different regions:

| Region |

Key Drivers |

Market Insights |

| North America |

High construction activity and stringent building codes |

The US market leads in stainless steel tube consumption, with a growing trend towards specialty grades for specific applications. |

| Europe |

Strict environmental regulations and a focus on sustainability |

European manufacturers are adopting eco-friendly production methods, leading to increased demand for recycled content tubes. |

| Asia Pacific |

Rapid urbanization and infrastructure development |

China and India dominate the region’s market, with a surge in construction and industrial projects driving stainless steel tube utilization. |

| Middle East & Africa |

Expanding oil and gas sectors |

The MEA region showcases substantial growth, particularly in oil and gas infrastructure, boosting demand for high-quality stainless steel tubes. |

Trending Shifts:

- Sustainability Focus: There is a growing emphasis on environmentally friendly production processes and materials with recycled content, reflecting global sustainability goals.

- Specialty Grades: The market is witnessing an increase in demand for custom-made, high-performance grades tailored to specific industry needs.

- Digitalization: Advanced manufacturing technologies, such as 3D printing, are transforming tube production, offering enhanced design flexibility and precision.

Economic Considerations: Driving Market Dynamics

Market Overview:

The global stainless steel square tube market exhibits dynamic characteristics, influenced by fluctuations in raw material prices, industrial growth, and regional economic factors. According to industry reports, the market size is projected to reach USD 25.6 billion by 2027, showcasing steady growth.

Investment Patterns:

- Manufacturing Infrastructure: Significant investments are directed towards establishing and expanding tube manufacturing facilities, particularly in regions with growing demand.

- Research & Development (R&D): Companies allocate substantial resources to R&D, focusing on developing new grades, improving production methods, and enhancing product performance.

- Supply Chain Management: Efficient supply chain networks are crucial for meeting market demands promptly, leading to strategic partnerships and logistics optimization.

Economic Impact:

- Job Creation: The industry contributes to employment generation, with a substantial workforce involved in manufacturing, sales, and support services.

- Trade Relations: Stainless steel tube trade plays a vital role in international commerce, influencing bilateral and multilateral economic relationships.

- Industrial Growth: These tubes serve as critical components in various industries, fostering economic development and diversification.

Technological Advancements: Revolutionizing the Landscape

Innovation Highlights:

- Welded Tube Production: Advanced welding techniques, such as laser welding, have improved tube fabrication, ensuring stronger welds and enhanced structural integrity.

- Surface Treatments: Various surface treatments, like passivation and polishing, enhance corrosion resistance and aesthetic appeal, catering to specific industry requirements.

- Computer-Aided Design (CAD): CAD software enables precise design and customization of stainless steel tubes, streamlining manufacturing processes.

Impact on Performance:

- Enhanced Strength: Newer production methods have led to higher strength grades, enabling their use in critical applications like aerospace and high-pressure systems.

- Improved Corrosion Resistance: Specialized coatings and surface treatments provide enhanced protection against corrosive environments, extending the lifespan of these tubes.

- Lightweighting: Technological advancements contribute to lightweight designs, reducing material usage and optimizing structural efficiency.

Future Potential:

- Additive Manufacturing: 3D printing offers unprecedented design freedom, potentially leading to customized, complex tube geometries for specialized applications.

- Smart Tubes: Integration of sensors and connectivity could transform these tubes into intelligent components, facilitating real-time monitoring and control in industrial settings.

- Biocompatible Materials: Advancements in biomedically approved stainless steel grades may open doors for medical device manufacturing.

Policy and Regulation: Navigating Legal Landscapes

Key Policies and Frameworks:

- International Standards: Organizations like ASTM International and ISO set global standards for stainless steel tube specifications, ensuring quality and consistency.

- Environmental Regulations: Various countries have implemented strict environmental policies, impacting tube production methods and material choices. For instance, the EU’s REACH regulation requires thorough chemical evaluation and management.

- Safety Standards: Industries with high-risk applications impose stringent safety standards, dictating specific tube qualities and testing protocols.

Regulatory Influence:

- Material Compliance: Manufacturers must adhere to specified composition limits and alloy grades to meet regulatory requirements, ensuring product safety and consistency.

- Production Methods: Regulatory bodies oversee production processes, especially concerning emissions control and waste management in steel manufacturing.

- Export/Import Controls: Trade regulations impact the global movement of stainless steel tubes, influencing supply chain dynamics.

Challenges and Criticisms: Overcoming Obstacles

Main Concerns:

- Cost Variability: Fluctuating raw material prices can significantly impact tube costs, posing challenges for manufacturers and end-users.

- Supply Chain Disruptions: Global supply chains are vulnerable to geopolitical tensions and natural disasters, leading to unpredictable delivery times and prices.

- Environmental Impact: Despite sustainability efforts, the steel manufacturing process contributes to environmental concerns, requiring continued innovation.

Proposed Solutions:

- Diversified Sourcing: Implementing strategic sourcing strategies, including exploring alternative raw material sources, can mitigate cost volatility.

- Resilient Supply Chains: Building adaptable supply chain networks and fostering local production capabilities enhance resilience.

- Green Technologies: Investing in environmentally friendly production processes, such as electric arc furnaces, reduces the carbon footprint of stainless steel manufacturing.

Case Studies: Real-World Success Stories

1. Construction Innovation: The Sky-High Tower

In a bustling metropolis, a groundbreaking construction project showcased the exceptional performance of stainless steel square tubes. A 500-meter-tall skyscraper, designed with a unique spiral structure, relied heavily on these tubes for its framework. The project’s success attributed to:

- Structural Integrity: Stainless steel tubes provided the necessary strength and stability, enabling the daring architectural design.

- Corrosion Resistance: The tower’s exterior, exposed to harsh weather conditions, remained intact due to the tubes’ superior corrosion resistance.

- Sustainable Design: Recycled content tubes were incorporated, aligning with the project’s eco-friendly objectives.

2. Automotive Efficiency: Lightening the Load

A leading automotive manufacturer revolutionized their vehicle models by incorporating stainless steel square tubes in key structural components. This strategy led to:

- Weight Reduction: The tubes’ lightweight design contributed to a 15% reduction in overall vehicle weight, improving fuel efficiency.

- Strength and Safety: Enhanced structural rigidity increased vehicle safety during high-speed collisions.

- Durability: Stainless steel’s resistance to fatigue and corrosion ensured the longevity of the vehicle’s chassis.

3. Medical Device Precision: Life-Saving Tubes

A medical device manufacturer utilized specialized stainless steel square tubes for precision components in advanced surgical equipment. The collaboration resulted in:

- Biocompatibility: High-grade, biomedically approved tubes ensured patient safety and compatibility with bodily tissues.

- Precision Engineering: Tight tolerances and precise dimensions enabled the creation of intricate medical devices, enhancing surgical outcomes.

- Reliability: The tubes’ consistent performance under sterile conditions was vital for reliable device functionality.

Future Prospects: Charting New Courses

Potential Growth Areas:

- Renewable Energy Infrastructure: Stainless steel square tubes are poised to play a significant role in the rise of renewable energy, supporting wind turbine construction and solar panel mounting systems.

- 3D Printing Applications: Additive manufacturing technologies will unlock new possibilities for complex tube designs, catering to specialized industries like aerospace and medical devices.

- Smart Cities and Infrastructure: As cities embrace smart technology, these tubes could become integral components in sensors, monitoring systems, and connected infrastructure.

Emerging Trends:

- Customized Solutions: The demand for tailored tube specifications will increase, driven by industry-specific requirements and advanced manufacturing capabilities.

- Sustainable Production: Environmental concerns will continue to shape production methods, encouraging the adoption of green technologies and recycled materials.

- Digital Twin Technology: Digital twins of stainless steel tubes could revolutionize quality control and performance prediction, enhancing design and manufacturing processes.

Strategic Considerations:

- Global Partnerships: Collaborating across borders can foster innovation, knowledge sharing, and market expansion, ensuring a competitive edge.

- Research Collaboration: Public-private partnerships for R&D will accelerate technological advancements, addressing industry challenges.

- Circular Economy Focus: Adopting circular economy principles can lead to more sustainable tube production, recycling, and re-use processes.

Conclusion: A Versatile Pillar of Modern Industry

The journey through stainless steel square tubes has unveiled their remarkable versatility, versatility, and profound impact across diverse sectors. From their historical evolution to cutting-edge technological advancements, these tubes have consistently adapted to meet the ever-changing demands of industry. As we look ahead, the future prospects for stainless steel square tubes appear promising, with potential applications in renewable energy, smart cities, and advanced manufacturing defining their trajectory.

By embracing innovation, addressing challenges, and navigating regulatory landscapes, the stainless steel square tube industry can continue to flourish, contributing significantly to global economic growth and technological progress. This comprehensive exploration highlights the importance of these unassuming yet powerful components that underpin modern civilization.

FAQ Section: Answering Common Queries

Q: What are the common applications of stainless steel square tubes?

A: Stainless steel square tubes find extensive use in construction, architecture, automotive manufacturing, medical equipment, wind turbines, and various industrial machinery due to their strength, corrosion resistance, and versatility.

Q: How do I choose the right grade of stainless steel tube for my project?

A: Select a grade based on your application requirements. Common grades like 304 and 316 offer broad-spectrum performance. Consider factors like corrosion environment, temperature, pressure, and mechanical properties to make an informed choice.

Q: Can stainless steel tubes be customized to specific dimensions?

A: Absolutely! Manufacturers can customize tube sizes to meet unique project needs. Customization ensures a perfect fit for specialized applications, although it may impact lead times and costs.

Q: Are there any environmental benefits associated with stainless steel square tubes?

A: Yes, stainless steel is a recyclable material, contributing to sustainable practices. Additionally, the use of recycled content tubes reduces the environmental footprint of manufacturing processes compared to virgin materials.

Q: How do I ensure the quality of stainless steel square tubes for critical applications?

A: Implement strict quality control measures during procurement, including material testing, dimensional inspection, and corrosion resistance evaluation. Reputable manufacturers with certified quality systems can assure consistent product quality.

Stainless steel square tubes from Steeline are ideal for farm buildings due to their exceptional strength, corrosion resistance, and aesthetic appeal. They offer long-lasting performance, reduce maintenance costs, and enhance structural integrit…….

Steeline Roofing Centre Bendigo provides top-quality stainless steel square tubes for robust, corrosion-resistant fencing solutions. Tailored to modern or traditional designs, these custom-cut tubes offer low-maintenance, strong fences enhancing…….

Steelee Bendigo offers a diverse range of stainless steel square tubes, catering to various architectural needs. These tubes balance strength and aesthetics, transforming functional components into design highlights. With exceptional durability,…….

Stainless steel is an ideal material for sheds due to its superior durability, low maintenance, and corrosion resistance. Steeleen Bendigo offers high-quality stainless steel square tubes perfect for shed construction, with advanced manufacturin…….

Stainless steel square tubing is a durable, corrosion-resistant material crucial for construction, manufacturing, and engineering. Its strength, stability, and chemical resistance make it ideal for demanding environments. Steeleen Bendigo specia…….

Steeline Roofing Centre Bendigo is a leading expert in stainless steel tubing for residential and commercial properties, offering tailored guidance, top-tier products, and long-lasting results. They provide diverse options, expert advice on grad…….

Steeline Roofing Centre Bendigo offers a comprehensive selection of stainless steel tubing for construction and roofing, catering to both professionals and DIYers. They provide tailored guidance based on industry trends and technologies, ensurin…….

Steeline Roofing Centre Bendigo offers high-quality, durable stainless steel square tubes resistant to rust and corrosion, ideal for industrial roofing and construction in harsh environments, providing long-lasting strength and structural integr…….

Using stainless steel for roofing frames in Bendigo is a smart choice due to its unparalleled longevity, strength, and corrosion resistance. Its high strength-to-weight ratio eases installation and reduces costs. Properly maintained, stainless s…….

Bendigo's architecture leverages stainless steel as a robust defense against harsh climate conditions. This material's superior corrosion resistance and durability ensure structures withstand extreme heat, cold, rain, and storms for ye…….

The Australian/New Zealand Standardization Body (AS/NZS) sets comprehensive standards for stainless steel square tubes, ensuring quality and performance across industries like construction, medical devices, and food processing. Steeline Bendigo…….

Steeline Roofing Centre Bendigo offers high-quality, corrosion-resistant stainless steel square tubes for durable roofing and outdoor applications. Their products provide reduced maintenance, increased lifespan, and enhanced structural stability…….

Stainless steel tubing from Steeline Roofing Centre Bendigo stands out for its superior strength, durability, and corrosion resistance. They offer precision-engineered solutions tailored to exacting industry standards, ideal for roofing, archite…….

Steeline Bendigo's stainless steel tubes excel in harsh weather due to their core material's exceptional corrosion, rust, and oxidation resistance. Crafted with chromium and nickel, this durable alloy maintains strength for years, even…….

Stainless steel tubing from Steeline Bendigo offers superior durability, corrosion resistance, and versatility for various industries. With bulk discounts, a comprehensive product range, and expert advice, they cater to construction, manufacturi…….

Steeline Roofing Centre Bendigo provides high-quality stainless steel square tubing for construction projects, catering to both residential and commercial needs. Known for durability, corrosion resistance, and aesthetic appeal, Steeline's p…….

Stainless steel square tubes are versatile, durable, and aesthetically pleasing, ideal for construction, furniture, automotive, and outdoor applications. Steeline Bendigo offers high-quality, commercial-grade tubes that meet stringent standards,…….

Stainless steel square tubes from Steeline offer superior durability and weather resistance for outdoor projects. Their premium material, with a protective oxide layer, resists corrosion and rust, ensuring long-lasting strength and aesthetic app…….

Steeline Roofing Centre Bendigo provides premium stainless steel tubing solutions for residential and commercial roofing needs. Their advanced manufacturing technologies and expert team craft durable, aesthetically pleasing tubes that meet high…….

Choosing stainless steel for shed construction offers exceptional strength, durability, and corrosion resistance. Steeline Bendigo provides high-quality stainless steel square tubes with seamless construction, enhancing garden aesthetics. Its ve…….